Using Azore CFD for Data Center Flow Modeling

By Kelly Hile

Azore CFD is a powerful tool for the optimization of data centers, particularly in helping reduce energy use and optimize cooling systems.

With an ever-increasing demand for cloud services, internet applications, and media streaming, modern computing depends heavily on the steady operation of data centers around the globe. The energy required to run a large data center can reach the equivalent of powering a small city. This extends beyond the electricity burden of the IT equipment itself. A significant portion of the energy cost is spent on simply keeping the equipment cool enough.

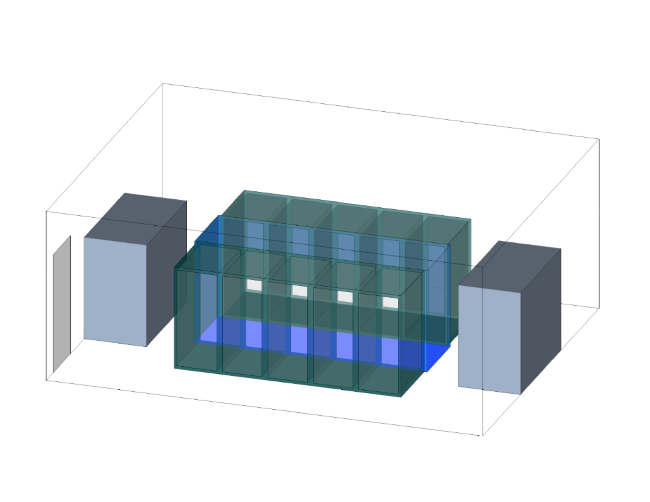

All data centers rely on cooling systems to keep equipment running in an optimal environment, which means keeping the air temperature and humidity in range. Not only does this prevent overheating of equipment and therefore server outages, but it also extends the operating life of servers and processors. IT equipment generates an immense amount of heat, which can build up in the room and in the worst cases cause fire and irreversible equipment damage. In the server room on the left, perforated floor tiles provide cool supply air to server intakes, while the aisle doors and roof keep warm exhaust air from mixing with supply air.

Cooling systems in data centers often account for over 30% of the energy cost and are the most opportune target for cost savings. By optimizing cooling equipment, HVAC, and room air flow, data centers can realize increased capacity, improved reliability, and lower operating expenses. But this process can be grueling, since it often means making making small incremental changes and observing what effects, if any, are made to cooling efficiency. For this reason, data center engineers are increasingly turning to Computational Fluid Dynamics (CFD) for analyzing data center cooling systems.

Even at its most basic licensing package, Azore CFD has all the tools needed to evaluate air flow within a data hall. This includes the ability to model air velocity, temperature, pressure, density and humidity at any location within the room.

Case Study: A Data Center With Cold Air Containment

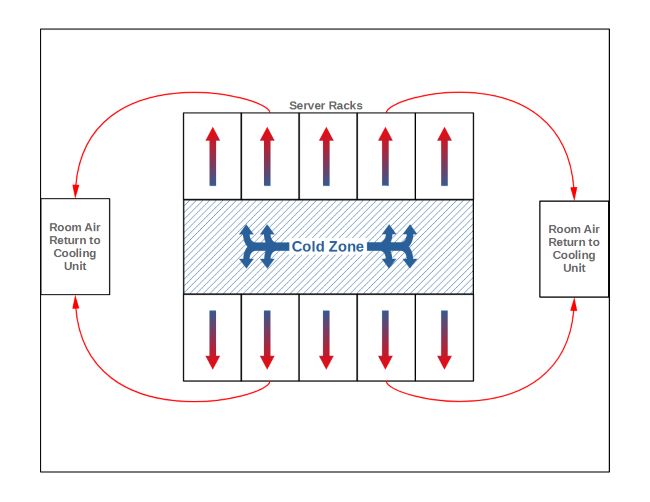

This Azore simulation shows how CFD can be used to validate a room setup. The data center is designed with a cold air containment aisle to ensure that as much cold supply air as possible flows through the equipment rack with minimum bypass. Cold air enters the room through perforated tiles in the aisle floor and flows through the racks, and as it does, it picks up heat from the equipment. After exiting the racks, the air flows to the return area where it will reenter the cooling system.

The CFD simulation models the air flow, heat transfer, and temperature mixing within the room. The goal is to prove out a room design that will keep the equipment cool enough and ensure that the flow patterns are not overworking the cooling system.

Uniform Velocity

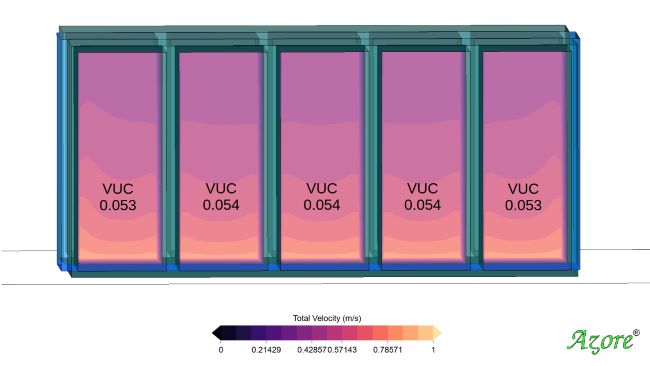

It’s important for the air to move through the racks at a uniform velocity, so that all areas of inside the racks receive a similar level of cooling. If there is too much variation in the flow, hot spots and overheating can occur in the equipment. Azore has the ability to quantify velocity uniformity so that users can easily compare the effectiveness of different designs.

The image below shows the velocity of the air as it exits each cabinet. The velocity uniformity coefficient (VUC) as determined by Azore is listed for each surface. An ideal design is one that will have a low VUC; Azore also displays velocity by color, making it easy to identify high and low spots.

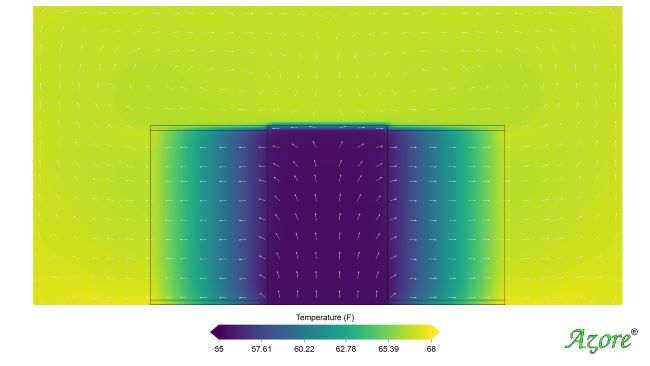

Equipment Temperature

The level of velocity uniformity directly affects the temperature inside the equipment. If air moves through the equipment quickly and evenly, the heat produced by servers will be properly dissipated. If any air slows down and spends too much time within the server, heat can build up. High temperatures mean lower hashrate, shorter device lifespan, and more frequent outages.

Since the Azore simulation also includes the effects of heat transfer, the results can tell us how the velocity affects the temperature, or cooling effectiveness, inside the racks. Because the velocity is uniform, the temperature is even and regulated across the equipment. The CFD results predict temperatures that are well within the recommended ASHRAE guidelines for this type of server room, ensuring that processors will operate at peak performance.

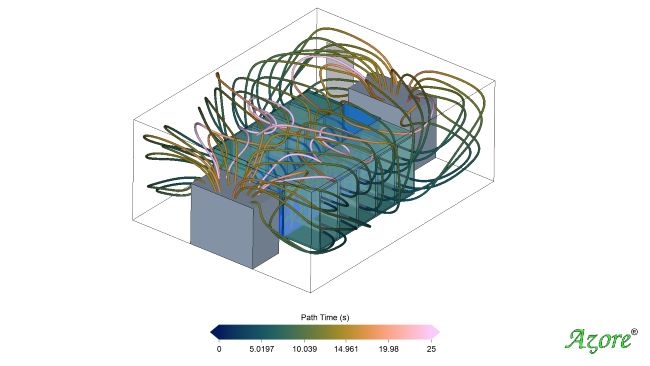

Stagnation zones

Even when the server racks are cool enough, stagnation zones within the room can cause cooling system inefficiencies. Stagnation zones, or areas where air is not experiencing much movement, are a common source of wasted energy in a cooling system. Ideally, all exhaust air from the equipment should travel directly back to the cooling units. Severe stagnation areas can be another source of heat buildup and cause an unnecessary rise in room temperature. In cases where there isn’t adequate containment in the cold aisle, stagnant air can lead to even bigger energy waste, such as the reingestion of warm air into the rack intakes.

Make Informed Decisions About Data Center Operations

With Azore, users can compare design options in a virtual setting and make decisions that consider the whole room. Once a data center is up and running, CFD can also be used to identify flow problems whenever performance issues arise. Until flow issues are resolved, a cooling system will be plagued by inefficiencies that require more power consumption, more online cooling units, more equipment maintenance, and higher operating costs. On the other hand, once a cooling system efficiency is maximized throughout the room, it often becomes possible to raise set point temperatures or even turn off redundant cooling units, resulting in incredible energy savings.

With the knowledge gained through CFD simulations, stakeholders can make confident decisions about improvements before capital expenses are made. In fact, Azore allows you to answer all sorts of questions about your data center that physical testing and trial-and-error analysis cannot.

- Does the data center have any hot spots, cold spots, or stagnant air?

- How will the cooling system respond to an expansion project?

- How can the cooling system adapt to dynamic room conditions such as load variations?

- How does the cooling system perform based on the season/climate?

- What are the effects of worst-case-scenario events such as power failures?

- What room layout or aisle set-up is best?

- What parameters have the biggest impact on cooling effectiveness (fan speed, location, supply air temperature)?

Azore CFD is an accurate, easy-to-use tool for analyzing air flow in data centers using CFD techniques, and our pricing options fit both small and large operations alike. All packages have the backing of high performance computing, parallel processing, and built-in tools for setting up a run and post-processing results. Not only do we offer competitive pricing, but you can try it risk-free for 30 days with our free trial.

Watch the tutorial: How to Set Up a Run