Engineering Challenge

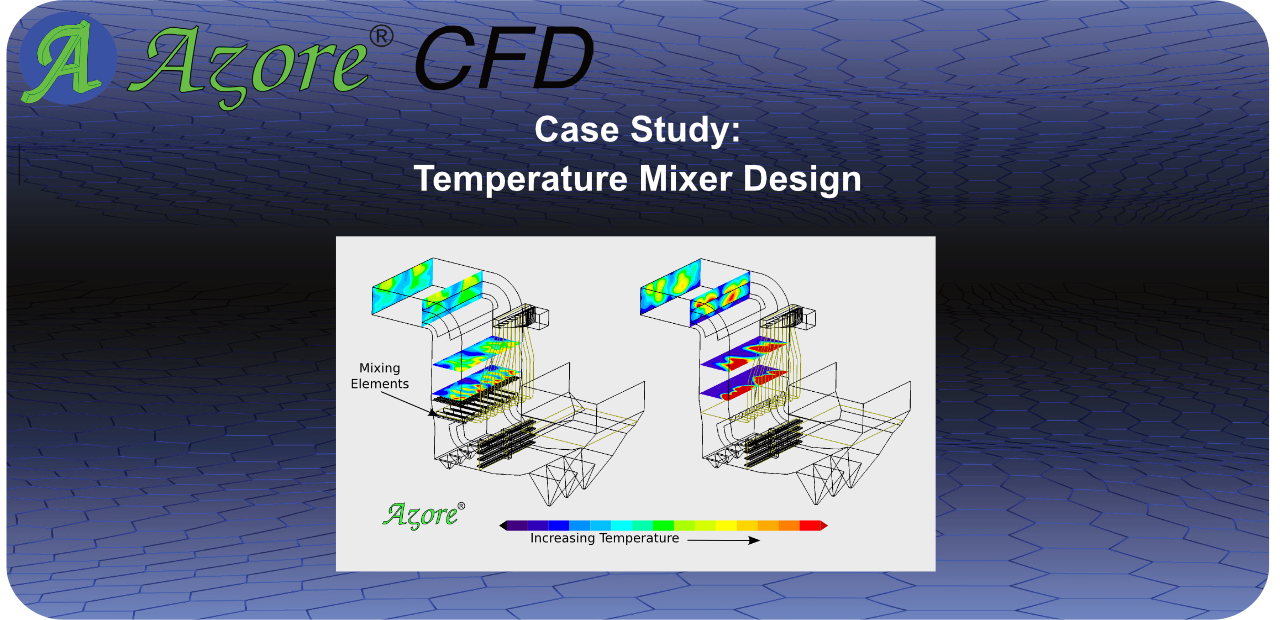

The challenge in this case is to predict the effectiveness of different flow mixer designs in a merging duct system. A hot gas stream is introduced through multiple feed ducts into a cold gas stream in a larger primary duct. A flow mixing device must be designed to achieve the proper mixing, and predictive simulations are required to achieve that design.

Azore Solution

Azore proves to be a very cost-effective solution for evaluating flows such as these and predicting the performance of the design candidates. Multiple objective functions that define the effectiveness of design are easily predicted using Azore CFD to simulate the complex physics involved. Employing polyhedral mesh strategies also simplify the task of modeling complex mixer designs.